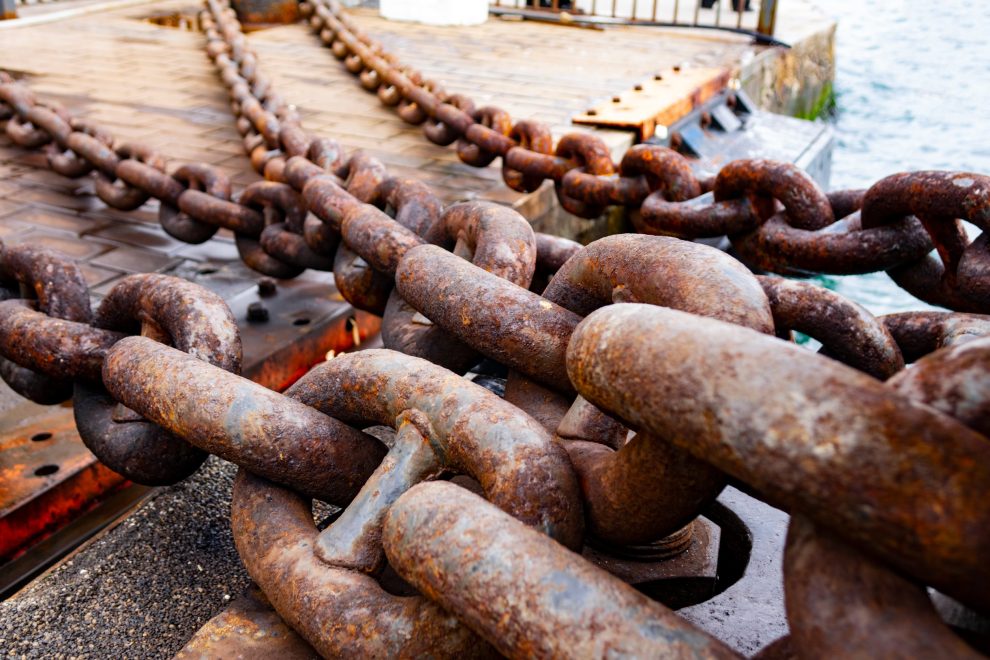

Rust, that reddish-brown coating that forms on iron, is a common phenomenon that occurs when iron reacts with oxygen and moisture. It is not only a cosmetic issue but also a sign of a chemical process known as corrosion. In this blog post, we will explore the fascinating world of rust, uncovering the reasons behind iron’s susceptibility to corrosion, the chemical reactions involved, and the ways to prevent and mitigate rust formation.

I. Understanding the Basics of Rust Rust is a form of corrosion that specifically affects iron and iron-based alloys. It occurs when iron reacts with oxygen in the presence of water or moisture. The chemical reaction leads to the formation of iron oxide, which is commonly known as rust. Rusting is a gradual process that can compromise the structural integrity of iron objects if left unchecked.

II. The Chemical Reactions Behind Rust Formation The formation of rust involves several chemical reactions. The first step is the oxidation of iron, where iron atoms lose electrons and transform into positively charged ions. These ions then react with oxygen to form iron(III) oxide, also known as rust. The presence of water or moisture accelerates the rusting process by providing the necessary medium for the chemical reactions to occur.

III. Factors Affecting Rust Formation Several factors influence the rate of rust formation on iron surfaces. These factors include humidity, temperature, the presence of salt or other electrolytes, and exposure to acidic or alkaline environments. High humidity and the presence of electrolytes, such as saltwater or acidic rain, increase the likelihood and speed of rust formation.

IV. Types of Rust Protection Preventing and controlling rust is crucial for preserving the integrity and longevity of iron objects. Various methods are employed to protect iron from rusting. These include applying protective coatings such as paint or corrosion-resistant coatings, using sacrificial anodes or galvanization, and employing proper maintenance practices such as regular cleaning and drying.

V. Rust Prevention Techniques In addition to protective coatings, several techniques can help prevent or minimize rust formation. These include the use of desiccants or moisture-absorbing materials to control humidity, applying corrosion inhibitors or rust converters, and implementing cathodic protection methods. Understanding the environmental conditions and employing appropriate preventive measures can significantly reduce the risk of rust formation.

VI. The Importance of Rust Prevention in Various Industries Rust prevention is vital in numerous industries where iron and iron-based alloys are utilized. In infrastructure and construction, rust can compromise the structural integrity of bridges, buildings, and pipelines. In the automotive and aerospace industries, rust can affect the performance and safety of vehicles and aircraft. Proper rust prevention measures are essential to ensure the reliability and longevity of these critical assets.

Conclusion: The process of rust formation on iron surfaces is a complex chemical reaction that occurs due to the interaction of iron, oxygen, and moisture. Understanding the factors influencing rust formation and employing effective prevention techniques are crucial for preserving the integrity and functionality of iron objects. By implementing appropriate protective measures and regularly maintaining iron surfaces, we can mitigate the impact of rust and ensure the longevity of our cherished iron-based possessions.

Add Comment